The Benefits of Custom Factory Solutions for Efficient Production Lines

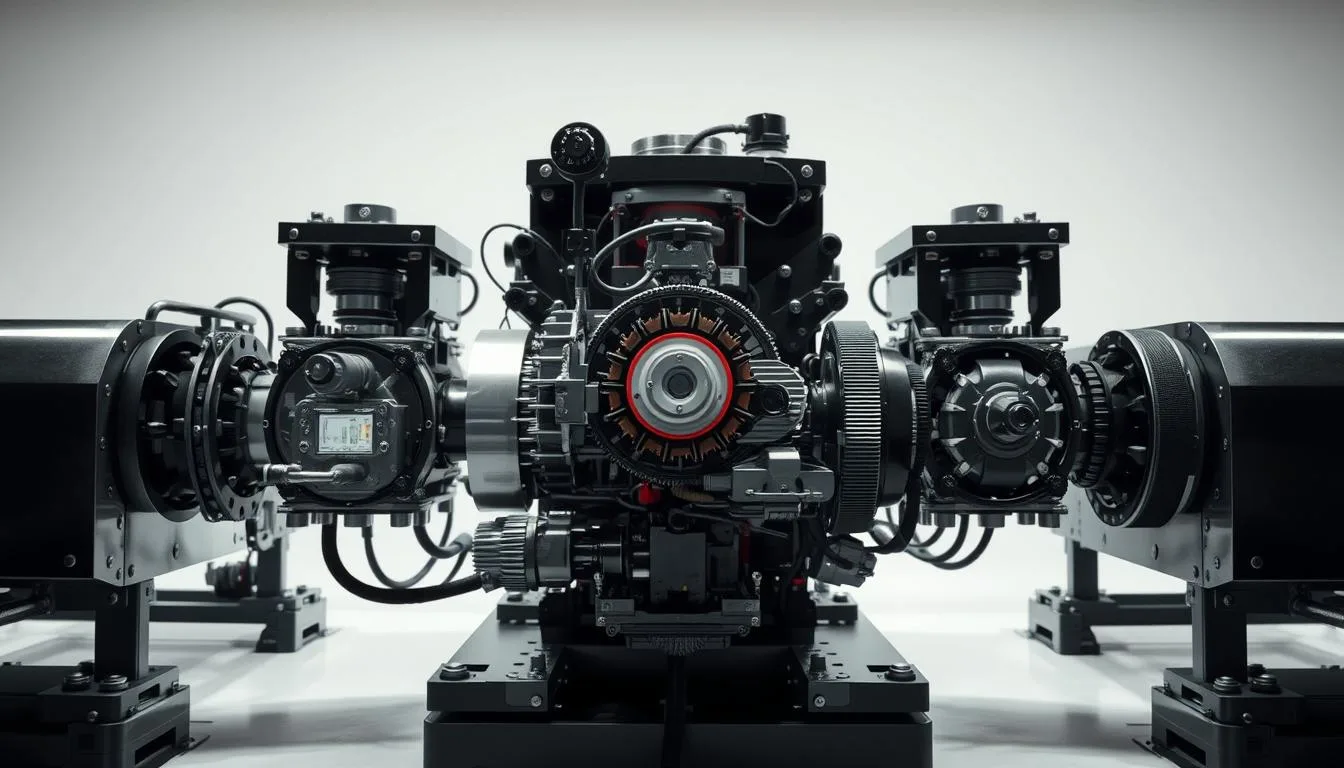

In today’s fast world, companies seek ways to boost production line efficiency and cut costs. Custom factory solutions offer tailored machinery and equipment for each line. This boosts efficiency and productivity.

These solutions bring many benefits. They improve efficiency, cut costs, and boost productivity. By using custom equipment, manufacturers can streamline their work, reduce waste, and work better.

Want to learn more about custom factory solutions? Contact us at info@skyltc.com or visit https://skyltc.com. Our team is ready to help with your production line needs. We believe custom solutions are key to efficient production.

Key Takeaways

- Custom factory solutions can improve production line efficiency and reduce costs.

- Tailored factory machinery and equipment can streamline workflow and increase productivity.

- Custom factory solutions can help manufacturers optimize their production processes and reduce waste.

- Implementing custom factory solutions can lead to increased efficiency and reduced costs.

- Custom factory solutions are tailored to meet the specific needs of each production line.

Understanding Custom Factory Solutions in Modern Manufacturing

Custom factory solutions are made to fit each production line’s unique needs. They consider things like product type, how much is made, and workflow needs. Our team of experts can help design and set up custom solutions for you. We use manufacturing automation to make things more efficient and cut costs.

The way we customize factories has changed a lot. Now, we have advanced custom manufacturing systems that can be adjusted for each line. Trends show a move towards more flexible and adaptable lines. This focus on production line optimization aims to boost overall performance.

Key Benefits of Custom Factory Solutions

- Improved efficiency and productivity

- Reduced production costs and increased profitability

- Enhanced product quality and consistency

Using custom factory solutions helps manufacturers stay competitive. They can reach their production goals. With our experts, you can get a solution that fits your needs and boosts your business.

Key Advantages of Production Line Optimization

Optimizing your production line can greatly improve your manufacturing efficiency and profits. By making factory workflow improvements, you can cut costs and boost productivity. This is done by using cost-saving factory solutions and industrial machinery tailored to your needs.

Some key benefits of optimizing your production line include:

- Reduced labor costs through automation and streamlined processes

- Improved product quality through reduced waste and increased precision

- Increased efficiency and productivity through optimized workflow and machinery

Investing in industrial machinery and cost-saving factory solutions can help manufacturers save money and stay ahead in their field. Factory workflow improvements also make employees happier and reduce turnover. Workers can focus on more important tasks in a better and safer work environment.

In summary, optimizing your production line is essential for better manufacturing efficiency and cost savings. By using cost-saving factory solutions and industrial machinery, manufacturers can meet their goals and stay competitive.

| Benefits of Production Line Optimization | Description |

|---|---|

| Reduced Labor Costs | Automation and streamlined processes reduce labor costs |

| Improved Product Quality | Reduced waste and increased precision improve product quality |

| Increased Efficiency and Productivity | Optimized workflow and machinery increase efficiency and productivity |

How Custom Factory Solutions Transform Manufacturing Efficiency

Custom factory solutions boost manufacturing efficiency by fitting machinery to each production line’s needs. This makes workflows smoother, cutting down on bottlenecks and boosting efficiency. With scalable solutions, manufacturers can adjust to volume or product changes easily, staying competitive.

Our custom factory solutions can boost your manufacturing efficiency and productivity. With designs that focus on flexibility and scalability, you can meet demand changes quickly. Key benefits include:

- Improved manufacturing productivity through streamlined workflow processes

- Reduced production bottlenecks and enhanced quality control measures

- Increased flexibility and scalability with scalable factory solutions

Investing in custom factory solutions can greatly improve operations. For example, better quality control means less waste and better products. Streamlined processes boost productivity and efficiency. With the right design, manufacturers can meet their goals and stay competitive.

Custom factory solutions are a powerful way to boost efficiency and drive success. By focusing on scalability, flexibility, and quality, manufacturers lay a strong foundation for growth and profit.

| Benefits | Description |

|---|---|

| Improved Productivity | Streamlined workflow processes and reduced production bottlenecks |

| Enhanced Quality Control | Reduced waste and improved product quality through tailored machinery and equipment |

| Increased Flexibility | Scalable factory solutions that can adapt to changes in production volume or product type |

Cost-Effective Implementation Strategies

Setting up custom factory solutions can be pricey at first. But, it can save money and boost efficiency over time. By using smart, cost-effective designs for industrial equipment, companies can cut costs and work better. Making production lines more efficient is key, as it cuts down on waste and boosts quality, saving money in the long run.

Some benefits of cost-saving factory solutions include:

- Reduced labor costs through automation

- Improved product quality through enhanced quality control measures

- Increased efficiency through streamlined workflow processes

We can help you set up custom factory solutions without breaking the bank. Our team will design and install equipment that fits your needs, cutting down on manual work and boosting efficiency. With better production lines, you’ll waste less and make better products, saving money over time.

Here is a comparison of the benefits of custom factory solutions:

| Benefit | Custom Factory Solutions | Traditional Factory Solutions |

|---|---|---|

| Cost Savings | Long-term cost savings through reduced labor and waste | Higher upfront costs with limited cost savings |

| Efficiency | Streamlined workflow processes and improved productivity | Inefficient workflow processes and reduced productivity |

| Quality Control | Enhanced quality control measures and improved product quality | Limited quality control measures and reduced product quality |

By investing in custom industrial equipment and making production lines better, companies can save money. They’ll work more efficiently, waste less, and make better products. Our team is here to guide you, from design to setup, to make sure your custom solutions meet your needs and save money in the long run.

Customization Options for Different Manufacturing Sectors

Custom factory solutions are available for many sectors like automotive, food and beverage, and electronics. Each field has its own needs and hurdles. Our solutions are made to fit these requirements.

Our team of experts can craft custom factory solutions for your industry. We use manufacturing automation and tailored machinery to boost production lines.

Industry-Specific Solutions

- Automotive: custom factory solutions for vehicle production, including welding, painting, and assembly

- Food and Beverage: custom factory solutions for food processing and packaging, ensuring efficiency and quality control

- Electronics: custom factory solutions for electronics manufacturing, including component assembly and testing

Custom factory solutions can make your production more efficient, cut costs, and boost productivity. Our experts can help you design a solution that fits your industry’s needs. This way, you get the most out of custom factory solutions and automation.

We aim to give you the best solution for your production line. Contact us to see how we can help you meet your manufacturing goals with custom factory solutions.

| Industry | Custom Factory Solution | Benefits |

|---|---|---|

| Automotive | Vehicle production optimization | Increased efficiency, reduced costs |

| Food and Beverage | Food processing and packaging optimization | Improved quality control, reduced waste |

| Electronics | Electronics manufacturing optimization | Increased productivity, reduced defects |

Integration of Smart Technology in Custom Solutions

Custom manufacturing systems can greatly benefit from smart technology. By adding sensors and automation, production lines can run better. This means less waste and more work done.

Industrial machinery can also be made to fit each production line’s needs. This smart technology boosts productivity.

Some key benefits of smart technology in custom manufacturing include:

- Improved efficiency and productivity

- Reduced costs and waste

- Enhanced quality control measures

We can help you add smart technology to your custom factory solutions. This brings many benefits to your business. With custom systems and smart machinery, you can make your manufacturing better and more competitive.

Investing in smart technology and custom systems can elevate your business. It improves efficiency, cuts costs, and boosts quality. Our team can design a custom solution for you. It will include production line optimization and smart machinery to enhance your process.

Measuring ROI from Custom Factory Solutions

Understanding the return on investment (ROI) is key for manufacturers with custom factory solutions. These solutions help improve productivity and save costs. To see how well they work, it’s important to look at financial gains, productivity, and long-term value.

We can help you understand the ROI of your custom factory solutions. We provide insights into their benefits and value. Our method includes analyzing financial benefits and how they impact revenue.

Key Performance Indicators

- Production line efficiency

- Quality control measures

- Waste reduction

By tracking these key areas, manufacturers can see how custom factory solutions affect their work. This info helps make smart choices for future investments. With the right solutions, companies can boost productivity, stay competitive, and grow profits.

We aim to give manufacturers the tools and knowledge to improve their production lines. By using custom factory solutions and cost-saving strategies, companies can lead the market and succeed in the long run.

Maintenance and Support Considerations

Maintenance and support are key for custom factory solutions. Custom industrial equipment is made to fit each production line’s needs. Regular upkeep stops downtime and cuts costs. Our team offers maintenance and support to keep your equipment running smoothly.

Our manufacturing automation systems use smart tech for real-time monitoring. This helps manufacturers improve their production line efficiency. With our factory design solutions, you can make your workflow better, reduce bottlenecks, and boost quality control. Our solutions are cost-effective and efficient for maintaining and supporting your equipment.

Our maintenance and support services offer many benefits:

- Less downtime and more productivity

- Better equipment efficiency and longer life

- Improved quality control and less waste

- Affordable maintenance and support options

Regular maintenance and support ensure your custom factory solutions work well. This leads to more productivity and lower costs.

Scaling Your Production with Flexible Solutions

Manufacturers often face challenges when they want to increase their production. Scalable factory solutions offer a flexible way to adapt to these changes. By using custom manufacturing systems, they can easily adjust to new demands.

Modular system design lets manufacturers tailor their production lines to their needs. This makes it easier to add new equipment or processes. It also helps in future-proofing, keeping the production line efficient over time.

Modular System Design

A modular system design breaks down a production line into individual modules. Each module has its own function. This setup allows for quick changes in production, making it easier to scale up or down.

- Increased flexibility

- Improved scalability

- Reduced production downtime

Future-Proofing Strategies

Future-proofing is key to keeping a production line efficient and effective. Implementing custom manufacturing systems tailored to specific needs is essential. This ensures the production line can adapt to changes in production volume or product type.

| Strategy | Benefit |

|---|---|

| Modular system design | Increased flexibility and scalability |

| Future-proofing | Improved efficiency and effectiveness |

Environmental Impact and Sustainability Benefits

Our custom factory solutions help you cut down on environmental harm and boost sustainability. They make workflow smoother and waste less, leading to better manufacturing productivity and lower costs. This is thanks to cost-saving factory solutions tailored for each production line.

Some key advantages of our custom factory solutions include:

- Less energy use

- Less waste

- Better sustainability

These benefits come from using custom factory solutions with green materials and practices. This reduces the environmental footprint of making things.

By choosing custom factory solutions, makers can boost their manufacturing productivity and help the planet. Our solutions aim for long-term benefits and support companies in reaching their green goals. They’re a smart choice for any business looking ahead.

Success Stories and Real-World Applications

Custom factory solutions have made a big difference in many industries. They’ve led to better efficiency, lower costs, and better quality control. Companies have seen big gains from manufacturing automation, making their production smoother and more productive.

For example, tailored factory machinery has been designed for specific needs. This has made production lines more flexible and adaptable. It’s worked well in the automotive, food and beverage, and electronics sectors.

Here are some real examples of how custom factory solutions have helped:

- Improved production efficiency through custom factory solutions

- Reduced costs and increased profitability through manufacturing automation

- Enhanced quality control measures through tailored factory machinery

| Industry | Custom Factory Solution | Benefits |

|---|---|---|

| Automotive | Tailored factory machinery | Improved production efficiency, reduced costs |

| Food and Beverage | Manufacturing automation | Enhanced quality control, increased productivity |

| Electronics | Custom factory solutions | Improved production flexibility, reduced waste |

These examples show how custom factory solutions boost productivity and cut down on waste.

Conclusion: Transforming Your Manufacturing Future with Custom Solutions

Custom factory solutions are key to moving forward in manufacturing. Working with leaders like Example Manufacturing Company can boost your production line efficiency. These custom solutions make workflows smoother, cut down on waste, and improve quality.

They bring real benefits to your bottom line and operations. Whether you’re in cars, food, or electronics, custom solutions fit your needs. They help you stay ahead with tailored factory machinery and the latest automation.

Starting your journey to excellence is easy. Just talk to our experts. Let’s work together to make your manufacturing better with custom solutions. We’ll help you reach new levels of efficiency, productivity, and profit.

FAQ

Custom factory solutions are special machines and equipment made for each production line. They make workflow smoother, cut down on delays, and boost productivity.

Custom solutions fit various sectors like automotive, food, and electronics. Each industry has unique needs, and solutions can be tailored to meet them.

While they can be a big investment, they offer long-term savings and efficiency. By planning carefully, manufacturers can cut costs and boost productivity.

Optimizing production lines leads to better workflow, less waste, and better quality. Custom solutions provide tailored equipment to meet each line’s needs.

They make manufacturing better by streamlining processes, cutting down on delays, and improving quality. They also help save money and increase productivity.

Smart tech adds benefits like better efficiency, lower costs, and quality control. Custom systems can use sensors and automation to optimize production and reduce waste.

It’s important to measure ROI to see the value of these solutions. Analyzing financial benefits, productivity, and long-term value helps understand their impact.

Regular maintenance and support are key to keeping solutions running smoothly. They prevent downtime and reduce costs, with smart tech providing real-time monitoring.

They can be designed to grow with production needs. Modular systems and future-proofing strategies make them flexible and adaptable for scaling.

They offer environmental benefits like less energy use, waste reduction, and sustainability. Streamlined processes and sustainable materials improve environmental impact and cut costs.

Yes, we have many case studies and testimonials showing their success. They highlight how custom solutions improve efficiency, reduce costs, and enhance quality.